Small things

Monday, April 20th, 2009I ordered the wrong size lugs so I sent them back for smaller ones. The screws for the batteries measures just over 5/16″ so I thought I needed to order the next size up – 3/8″. Turns out the lugs, at least the ones I got, are oversized so they were 0.05″ too big. The connections was a little sloppy so I’m going with the smaller size.

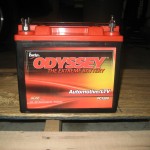

It works out well, because with the battery swap I’m going to need to use the SAE posts on top of the battery. The new battery has both SAE terminals on top and screw post on the side. If I want to put the batteries in rows front to back, the screws posts would not be accessible for the cable.

I also found a leak with the vacuum pump. When I put the muffler on the o-ring slipped to the side and wasn’t sealing right. While I had the reservior and pump off I added a pad beneath and to the side of the pump to keep it a little quieter.

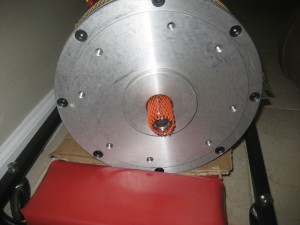

Other progress was painting and bolting up the motor mounts. I need 2 bushings and 2 more bolts and they’ll be done. I should take some more pictures.