Small progress

Tuesday, March 24th, 2009Not much change on the actual car, but I have been up to some stuff:

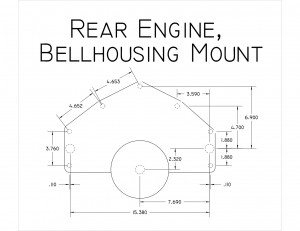

- Made wood mockups of motor mounts and then sketched them up. I’ll remake them and assembly from the sketches to see if it still makes sense.

- Thought a lot about the power steering and A/C pulley system. They rotate opposite directions so it’s a little more involved than hoping.

- Realized the placement of the battery terminals means that a cable won’t fit between the batteries unless I purposely use an odd battery arrangement. I have an idea on solving that…

- Got a new shipment of parts – battery lugs, plastic terminal covers, contactor, circuit breaker, fuse and holder

- Found the oversized 40 amp fuse at a boat store

- Found out the boat store has a cable crimper to make battery cables that customers are allowed to use, preferably if you bought your stuff there but they were pretty nice…

More later.